Ideal for the retail market, blister packing is most suited for smaller components such as; stationery and writing instruments, cosmetics, batteries, small home improvement, and spare parts.

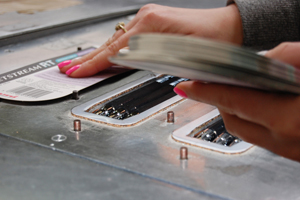

The method of blister packing uses a clear plastic blister to hold a product onto a printed backing card to your own design. The blister is sealed onto the card using a combination of pressure and heat. The clear plastic gives visibility to the product and the backing card is printed on both sides, which allows you to promote the product. A bar code is usually printed on the reverse of the backing card for Electronic Point of Sale (EPOS). If required, a euro slot can be cut into the top of the card for hanging on display.

Another version is to hold the blister between a folded card. The card is printed on one side and glued on the other. The advantage of this type of packing is that the blister rim is hidden between the card giving a slightly better appearance.Gemini Packing Services are able to supply both versions from design to delivery. We are able to provide blister packs to your specification including sourcing materials and all tooling required for each new project.